Gjysmë rimorkio me plan ngarkimi të ulët i ri Goldhofer 5-Achs-Tele-Semi mit hydr. Rampen MPA

Botuar: 1v 2m

Botuar: 1v 2m

Keni nevojë për transport?

Pre-purchase inspection

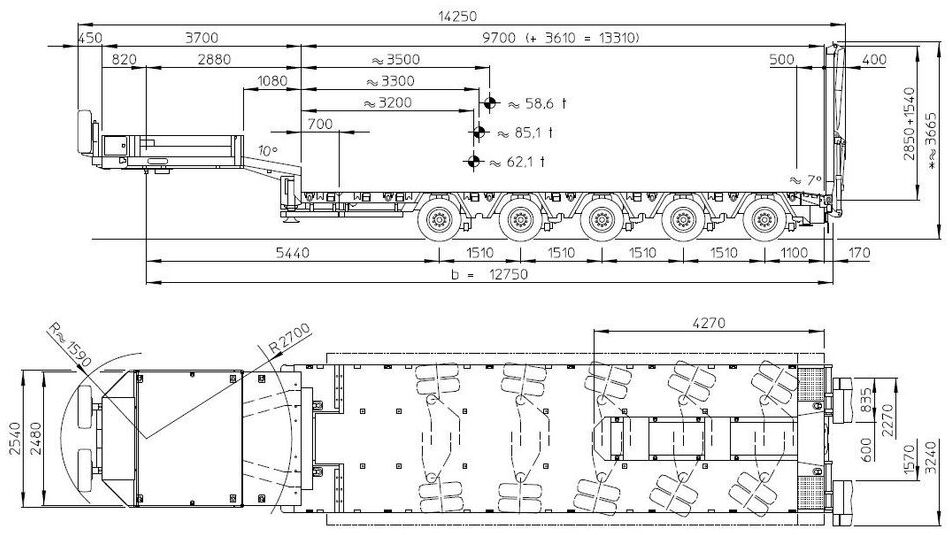

Pre-purchase inspectionGooseneck, fixed, with side members pulled outwards:

Loading area 3.700 mm x 2.480 mm

Beveled 10°, front corners 45°

1.080 mm long, 190 mm high bevel at the end of the gooseneck

including perforated strip for aluminum ramps

Maximum fifth wheel load 26.000 kg

Turning radius 2.700 mm for a 4-axle truck unit

3.5" king pin

Spacer plates with screws for fifth wheel height, loaded approx. 1.250 mm

Sheet metal flooring

Mechanically actuated landing legs (lifting capacity: 24.000 kg, static test load: 50.000 kg)

Aluminum side walls closed on 3 sides including rear side wall

1 piece on the side, 400 mm high

Stanchions, foldable and removable

3 pairs of lashing points LC 8.000 daN

1 pair of lashing points LC 3.000 daN

Loading area:

Outer and inner tube construction

With 700 mm long loading area section at the front

Loading area 9.700 mm x 2.750 mm, telescopic by approx. 3.610 mm to max. 13.310 mm

Without sliding table

Sheet metal flooring in the outer fields between the center tube and the outer frame

Locking of the extension steps by means of spring-loaded cylinders and cone bolts

(Increments of approx. 500 mm adapted to the requirements of circular travel - optimized for maximum extension. The load diagram must be observed here)

Preparation for attachable aluminum bridging rails, recess on the loading area part including chamfer on the outer frame

Traffideckgo / polymer floor covering with anti-slip covering in the outer areas of the loading area (without rear bevel) and on the fixed loading area part at the front

1 pair of lashing points LC 20.000 daN

1 pair of lashing points LC 10.000 daN

1 pair of stanchion pockets 100 x 50 mm (LC 2.000 daN)

2 pairs of threaded bush(es) M30 on the inner tube

Vehicle rear:

Beveled design (500 mm long, 7.6° bevel)

1.100 mm overhang from the middle of the last axle

Ramp eye removable at the final traverse

Hydraulic support for support during the loading process

Hege rubber / sheet metal floor covering

Suspension rails for aluminum docking ramps at the rear

Mounting bracket for oversized signs and warning light

Water absorbers on the vehicle

1 pair of lashing points LC 10.000 daN

1 pair of lashing points LC 20.000 daN

5-axle chassis (MacPherson axle technology):

1 self-steering axle, 4 self-steering axles

Axle make BPW Eco Plus

Running gear width 2.750 mm

Wheelbase, starting from the first axle 4 x 1.510 mm

Twin tires 245/70 R 17.5 143/141K (146/146F) profile HT3, 3PMS winter tires Conti

Hydraulic axle compensation, stroke 350 mm

Driving and loading height: 885 mm +250 mm / -100 mm

Sheet metal flooring

Excavator recess 4.270 mm long and 804 mm wide, 3 pairs of lashing points LC 3.000 daN

Splash protection device with water absorbing mats on all axles

1 set of axle tools

5 pairs of lashing points LC 10.000 daN

5 pairs of stanchion pockets 100 x 50 mm (LC 2.000 daN)

5 pairs of threaded bushes (M36) on the loading area (LC16.000 daN)

Braking system:

Drum brakes

Two-line four-wheel compressed air brake system with diaphragm brake cylinders

Automatic load-depended brake (ALB)

Automatic brake adjuster (AGS)

Spring controlled parking brake

EBS - brand KNORR-BREMSE, with ABS

Socket for EBS on the front of the gooseneck

RSP (Roll Stability Program)

TIM (Trailer Information Module), make Knorr:

Mileage

Aggregate load display / axle load display

EBS diagnosis

Sockets and lighting:

1x 15-pin on the front panel of the gooseneck for power supply, 24 V (ISO 12098)

2x 7-poles on the final traverse for 24 V warning signs

1x 7-pin on the final traverse for light bars (socket fully occupied) 24 V

2x 7-pin in the area of the seat posts for 24 V warning signs

1x 7-pin on the final traverse for rotating beacon (switched to light) 24V

1x 16-pin on the gooseneck for deflection

1x 7-pin on the final traverse for 24 V manual steering

1x NATO on the gooseneck for E-unit (VG 96917)

2x 7-pin between the 3rd and 4th axis for 24 V warning signs

1 piece warning light (LED) pluggable

Light Detection Load Module (LCG)

7-chamber LED light (without load module)

LED side marker light according to EU directives

1 pair of reversing lights in the light bar, switched to reverse gear

Work lights between the axles, controlled via switches in the chassis

Between axles 1 and 2

Between axles 4 and 5

Hydraulic lifting of the 1st axle in the chassis:

Through double-acting cylinders (not load-dependent)

Operation on the semi-trailer

Two-piece hydraulic ramps:

Length 2.850 mm + 1.540 mm, width 835 mm

Hydraulic ramp hoist

Hegegummi floor covering, with climbing rails

On the outside of the ramp 20 mm x 20 mm x 215 mm, Hardox 450

Maximum loading capacity per pair of ramps 80.000 kg

Can be moved laterally by means of a hydraulic cylinder to a maximum external width of 3.240 mm or a minimum internal distance of 600 mm

Integrated mechanical locking in the ramp lifting cylinder to secure the ramp in the transport position

Bracket for warning light on left ramp, inside

Electro-Hydraulic unit, 5.5 l / min:

Make Bosch

Including 2-pole coiled cable with connectors and screw ring (length 4m)

Goldhofer SmartControl:

The following functions can be operated using the radio remote control or the keypad on the gooseneck and/or on the left of the rear of the vehicle:

Tracking and re-tracking

Switching the worklights on and off via power PIN 10

Raise / lower the hydraulic liftable axle(s)

Starting and stopping the truck motors if this is supported by the tractor (PIN 13 = release signal; PIN 14 = stop; PIN 15 = start)

Raising and lowering the driving level and approaching the stored driving positions

Control of the hydraulic rear support

Control of the hydraulic ramp hoist

Hydraulic ramp shift control

Additional "Seidl" radio remote control for master/slave switching (follow-up steering and re-alignment, work lights, steering pressure)

6-way block tap in the gooseneck:

To depressurize the gooseneck linkage

Flow divider:

For an increased tractor capacity of up to 120 l/min

Paintwork:

Pre-treatment: Steel construction according to DIN 55928 and ISO standard 8501 SA 2.5 blasted with corundum, metallization according to DIN EN ISO 2063 (thermal spray galvanizing with 99.995% zinc content)

Paint structure: first coat with 2-component zinc dust primer (89% zinc content), second coat with EP/2-component PUR adhesion primer, third and fourth coat with 2-component PUR top coat, cavities with EP/2 -K-PUR primer and 2-K-PUR topcoat sealed, paint structure tested according to salt spray test DIN EN ISO 9227, connecting parts with zinc flake / zinc-nickel coating, preservation with material resistant to steam jets

Painting in single colour DB7350 – nova grey

Attachments: DB7350 – nova grey

Rims: silver

Hubs: black

Drop sides: anodised aluminum (silver)

Stanchions for side walls: in RAL 9006 white aluminium

Storage box on gooseneck: powder-coated in RAL 9006 white aluminum

Anti-slip coating on all treads

Additional equipment:

2 spare wheel holders on the front of the gooseneck, pluggable, galvanized

2 spare wheels

Additional 2” king pin supplied loose

Parking position of the tailgate on the gooseneck at the front

2 pairs of wheel chocks including holder

Goldhofer "Premium" storage box, mounted on the front of the gooseneck, corners bevelled at 45°, dimensions approx. 550 x 400 x 2,540 mm, with side doors and rectangular cover that can be folded forwards, lockable doors and cover, 2 plug-in partitions on the inside.

2 pairs of warning signs, 423 x 423 mm, with 3 LED position lights, including tube for warning light, holder for warning signs (rectangular tube), pluggable for a maximum width of 4.200 mm.

Extensions extendable by 220 mm each, including extension boards made of larch, 70 mm (max. extendable by approx. 320 mm each, but with the same extension boards)

Designed for a chain center of up to max. 2.800 mm.

Extension element that can be hooked into the rear of the vehicle. Larch floor covering.

1 pair of lashing point(s) M30 screwable LC=10.000 daN

1 pair of lashing point(s) M36 screwable LC=16.000 daN

1 set of hydraulic connections for tractor unit, without lines

Central lubrication system, "Progressive" type for normal grease, 1 quick filling kit of the central lubrication system

Keni nevojë për transport?

Merrni një kuotë transporti

Keni nevojë për transport?

Merrni një kuotë transporti